Build and Test of Open Source 3D-Printed 10 mL Syringe Pipette

Overview and Scope:

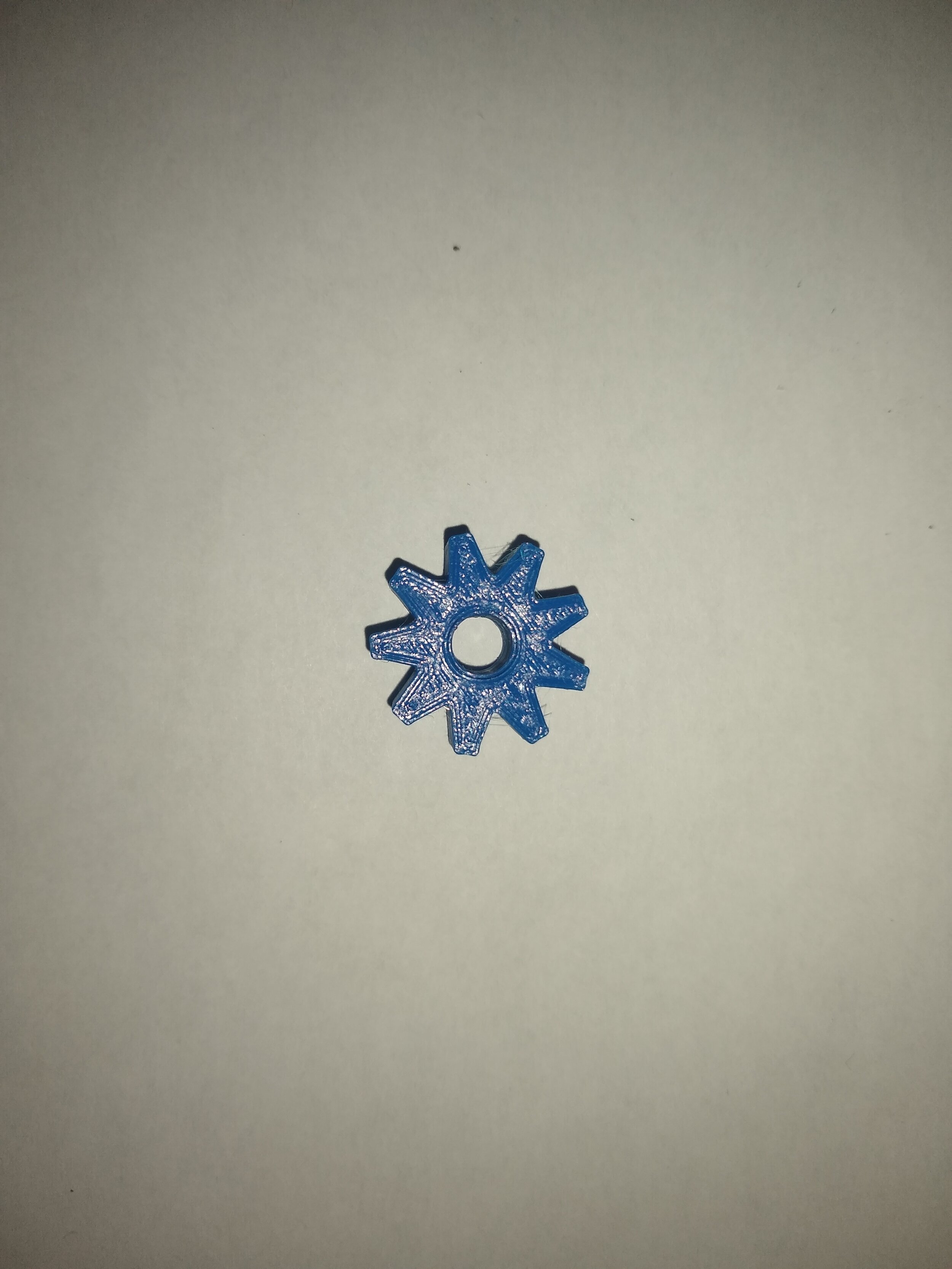

In this post we build and test an open source 3D printed 10 mL syringe pipette. The files for this post were uploaded by JorBraMar on Thingiverse. This build is a continuation of the construction of a series of pipettes, which originated from the recreation of the open source 3D printed 1000 μL micropump. This 10 mL syringe pipette is much simpler to make than the 1000 μL micropump because it consists of only three, 3D-printed parts, a 5M x 25mm headless screw, and a 10 mL syringe. This apparatus allows one to manipulate a sterile 10 mL syringe with one hand. This is helpful, as the manipulation of a syringe usually requires the use of two hands; one hand is used to hold the body of the syringe, while the other hand is used to draw the plunger. This design allows for one to hold the syringe body using the apparatus, while simultaneously manipulating the syringe plunger by rotating the gear (which engages and moves the slide mechanism) with the thumb of the same hand. We seek to outline the construction and feasibility of such a device in this post.

Parts List:

Ender 3 V2 3D Printer

PLA (or any other filament of choice) - Used eSUN PLA PRO (PLA+) 3D Printer Filament, Dimensional Accuracy +/- 0.03mm, 1kg Spool, 1.75mm, Blue - https://www.amazon.com/dp/B01EKEMNRO/ref=twister_B095MTT7D3?_encoding=UTF8&psc=1

General tools: hex keys, screwdrivers, sandpaper, etc.

STL files - https://www.thingiverse.com/thing:2400841 or files found in https://www.thingiverse.com/thing:2400841/files

1x - 5M x 25mm headless socket screw (substituted with a 10-24 x 1” headless socket screw)

1x - 10 mL generic luer lock syringe

Printer Settings:

Sliced using Ultimaker Cura 4.10.0

Filament: eSUN PLA PRO (PLA+) 3D Printer Filament, Dimensional Accuracy +/- 0.03mm, 1kg Spool, 1.75mm, Blue

Standard Quality - Resolution: 0.20mm

Infill: 50% for all components

Supports: tree, 45% overhang, zigzag pattern

Extruder Temperature: 215°C

Bed Temperature: 60°C

NOTE: See publication for original printing parameters

Components and STL Files:

There are three components which need to be 3D printed for this 10 mL Syringe Pipette

The files used for the print in this post were found and retrieved from an upload by JorBraMar on Thingiverse: https://www.thingiverse.com/thing:2400841

Assembly:

See the author’s original post for instructions. The PDF document titled, Instructions.pdf, is included in the uploaded files on Thingiverse and provides the specific print parameters and assembly instructions.

Thingiverse files link: https://www.thingiverse.com/thing:2400841/files

The only deviation from the instructions provided were the addition of a rubber band to hold the syringe body and the substitution of the 5M x 25mm headless socket screw with a 10-24 x 1” headless socket screw.

Discussion:

The apparatus printed flawlessly, was easy to assemble, and was user friendly. The finished 10 mL syringe pipette worked very well when tested. The only deviation from the instructions provided were the addition of a rubber band to hold the syringe body in place, as well as the substitution of the 5M x 25mm headless socket screw with a 10-24 x 1” headless socket screw. The 3D printed body and slide have a sufficiently large enough slot to theoretically hold any type of 10 mL syringe and there are no issues with the design whatsoever. The design of this apparatus suits circular and oval plunger flanges of many sizes. The specific syringe used in this recreation had a small, circular plunger flange, which caused it to slip out of the slot in the slide when strained. If the syringe used in this post had an oval shaped syringe plunger flange, or even a slightly larger diameter syringe plunger flange, it would have fit perfectly and not required the use of a rubber band. The utility of this device lies in the fact that it can be used for sterile syringes and allows for the user to not have to touch the syringe to use it. The syringe can then be easily removed and replaced with a new, sterile syringe after each usage. Overall, this is an impressive, user friendly design which is mechanically streamlined. It is also very utilitarian and can easily accept many different types of 10 mL syringes.