The Superior Mechanical Properties of Light Link™ SLA Resin

SLA 3D printing is expanding the boundaries of high resolution 3D printing. However, there is an ongoing discussion on how to overcome the brittle nature of many 3D printed SLA resins.

SLA 3D printing resins consist of an intricate mixture of methacrylate oligomers, methacrylate monomers, photoinitiators, and UV blockers. The mixture, called a resin, is poured into the vat of a 3D printer. The final object is printed layer-by-layer, through UV light induced photo-polymerization. UV light initiates a chemical reaction which enables monomers to form covalent bonds with one another. This process is generally carried out via a free radical mechanism.

SLA 3D printing resins require an enormous amount of skill to properly construct. Tedious formulation work, using a series of trial-and-error experiments, appears to be the only method to make 3D printing resins. Therefore, the exact composition of most commercial resins remains a closely guarded secret. The most common method to gain insight into the composition of these resins is through examination of the notorious PR48-Clear Prototyping Resin. This is the only resin, which we are aware of, that has a publicly disclosed composition. The exact composition of PR48 is as follows (percentages in wt/wt):

Photoinitiator: 2,4,6-Trimethylbenzoyl-diphenyl-phosphineoxide (TPO) 0.40%

UV blocker: 2,2’-(2,5-thiophenediyl)bis(5-tert-butylbenzoxazole) (OB+) 0.16 %

Reactive diluent: Genomer 1122 19.89%

Oligomer: Ebecryl 8210 39.78%, Sartomer SR 494 39.77%

Source: https://3dprint.com/50225/autodesk-ember-pr48-resin/

3D printing resins must be well balanced to achieve proper functionality. There are two important considerations when attempting to make such a masterpiece; ease-of-use and mechanical properties. Concerting these interconnected attributes is key to making a successful resin.

We take our 3D printing resins seriously!

The 3D printing resin marketplace is saturated with new resins. From the perspective of one who is skilled in the art, many resins appear to be composed of the same substituents. Manufacturers may simply add a pigment to their current resin and then market it as a new resin with Woo-Woo qualities. Wash, Rinse, Repeat. Many commercial resins are continuously re-branded for different markets. In many cases, the only differentiation between commercial resins is excellent marketing.

We set out to make a novel SLA 3D printing resin. We spent a lot of time carefully constructing Light Link™. We rigorously tested our resin to ensure that it meets the highest standards of testing. High tensile strength is only one of the many attributes that differentiates Light Link™ from the others.

The late Terence Mckenna once stated, “The universe is a novelty-conserving engine: it produces novelty and then it acts to hang on to it. And it uses that novelty to build the next level of novelty.”

We embrace novelty. We cherish novelty. We exist “to build the next level of novelty.”

This is why we created Light Link™.

Tensile Testing of Commercial Resins

We have tested numerous commercial resins with a series of standardized testing protocols. We found that the Ultimate Tensile Strength of most resins is between 25 - 35 MPa. Many of these resins claim an Ultimate Tensile Strength of 45 MPa or higher. Here are the results of only three commercial resins that we have tensile tested:

DruckWege - Type D Standard DLP/LCD Resin

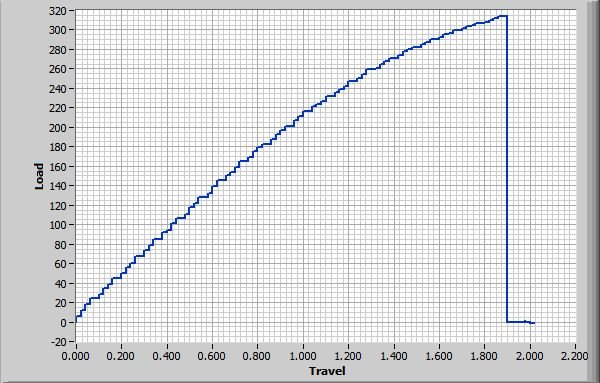

DruckWege reports a Tensile Strength of 36.6 MPa for their Type D Standard resin. We measured an Ultimate Tensile Strength of 33 MPa with an average 1.8% Elongation at Failure. At the proper exposure time, we consistently measured an Ultimate Tensile Strength of 36 MPa. Therefore, we obtained results which were fairly close to the reported tensile strength. However, when using exposure times that gave the highest tensile strength values, we encountered issues with brittleness. This made it difficult to remove the Type V dog-bones from the build plate without breaking them. Click the link below to view the raw data.

FormLabs BioMed Clear V1 Resin

FL reports an Ultimate Tensile Strength of 52 MPa with 12% Elongation at Failure for their BioMed Clear V1 resin. We measured an Ultimate Tensile Strength of 27 MPa with a 5.8% Elongation at Failure for tensile test specimen that were printed on the FormLabs Form 2. This represents the lower end of the measured tensile strength for this resin. When tensile test specimen were printed using an Elegoo Saturn, we repeatedly measured an Ultimate Tensile Strength of about 30-32 MPa with a 6.0% Elongation at Failure. Click the link below to view the raw data.

Elegoo ABS-Like Grey Resin

We measured an Ultimate Tensile Strength of around 21 MPa with a 5.0% Elongation at Failure. Click the link below to view the raw data.